Find a complete range of Brass Products under one roof!

About Us

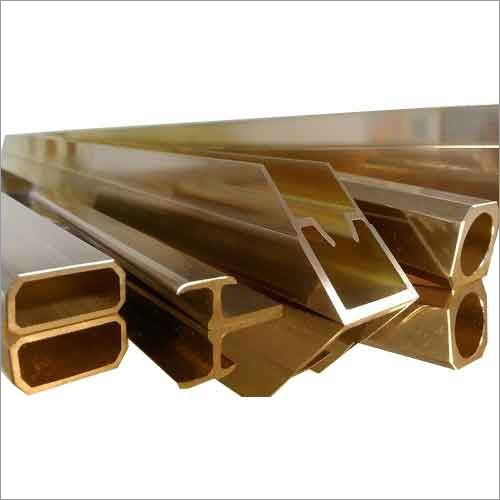

Formerly known as Brassomelt Extrusions Pvt. Ltd., we are Marvel Extrusions, an industry leading manufacturer and exporter of a variety of Brass Products. From Rods, Profiles, Wire Coils to Ingots made in the finest of brass, we have various products under our wide portfolio, all fabricated complying to international standards of BIS, DN, IS, GOST, ASTMD and others. We can even construct products as per specified drawings or samples, as provided by customers.

Since we established our firm in 2017, we have been moving ahead in business with the goal to deliver top-rated Brass Ingots, Solid Brass Rods, etc., that are matchless in terms of electrical or thermal conductivity, construction, corrosion resistance, impact resistance and machinability. In all these years, we have managed introducing the highest quality Brass Products at the most affordable prices, therefore serving countless customers with excellence from the following sectors:

- Electrical Wiring & Earthing Accessories

- Defence

- Electrical Contacts

- Automobile

- Brass Hardware Fittings

- Battery Terminals

- Electronics

- Pipe Fittings & Connector Parts

- Imitation Jewellery

- Fasteners, etc.

Why Us?

We have been making steady progress in our field because of the following reasons:

- We create outstanding quality products as per international standards.

- Our Brass Products are the most competitive in the entire world market.

- We always accomplish our production targets and arrange for quick deliveries.

- As much as we are growth oriented, we are also client focused.

- We believe in maintaining close communication with clients.

- Our products like Brass Ingots, Solid Brass Rods, etc., are built around the latest technological advances in the field.

Infrastructure

Our premises integrated with separate work areas facilitates division of work in the most effective way. Besides, being based in a developed industrial corridor, our setup allows for easier and quicker movement of both raw materials and end products. We boast of an annual installed capacity of almost 5000 MT and strive towards improving this capacity at a rate of 10% every year.

Currently, our manufacturing plant is outfitted with many robust machines, such as:

- Hydraulic Billet Cutter

- Billet Heating Furnace

- Medium frequency Coreless Induction Melting Furnace (fitted with heavy-duty Twin Melting Pots & Power Trak-R Plus)

- 425 M.T. Extrusion Press with Oil filtration plant installed

- Reeling Machines with variable speeds

- Pickering Plant

- Annealing Furnace

- Ultra Modern Draw Benches

- Modern Cutting & Parting Machines

- Straightening Machines

- Precision Pointing Machines

We also have Lathe Machine, Hacksaw & Grinding Machines, etc., in our tool room.

Our Goal- Environmental Protection

- Water: We have effluent water treatment plant that helps in recycling and reusing water for manufacturing work.

- Energy: Extra capacitors are installed at our plants for managing and controlling reactive & non-reactive power losses. Our workforce is trained on the benefits of energy efficiency & savings.

- Air: After passing through chimneys, various exhaust hot gases and zinc oxide are collected through bag houses. Bag house drums collect the zinc oxides, which ensures only oxide-free gases are released. The zinc oxide ash we collect is then further sold to government authorized processors.

We also minimize waste generation in our work as per the Industrial Waste Management policies and protocols that we have in place. Moreover, hazardous and toxic solid waste materials are only disposed at authorized and government nominated dumping sites.

Make your

enquiry now !

Talk to us! we will be glad to assist

you.

Product Gallery

|

MARVEL EXTRUSIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese